Roads and Railways

Works such as roads and railways need to be designed accurately to ensure their durability and user security.

Tenax geosynthetics can be used for base reinforcement, construction of road and railway embankments, retaining works such as reinforced soil walls, block walls or panel walls, and slope erosion control.

Base reinforcement

The innovative Tenax 3D GRID have been developed to minimize settlements of roads or railways, where the longitudinal load can create dangerous settlements in the asphalt or the railway track, reducing the service life of the work.

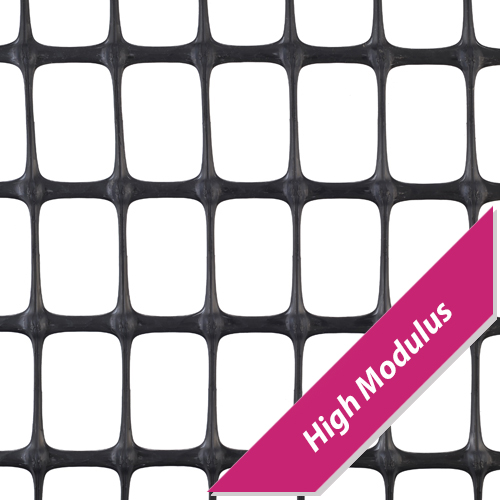

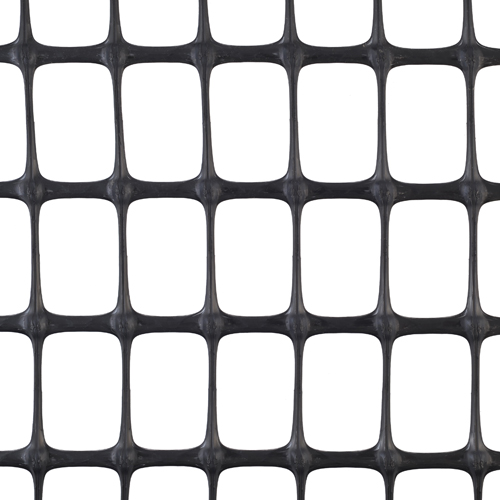

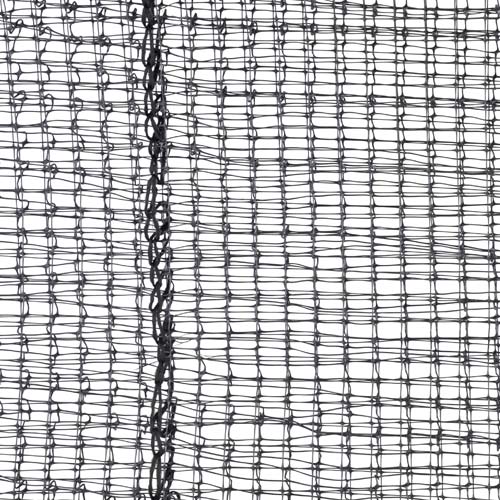

In order to increase the bearing capacity of the foundation soil of an embankment, the geogrids must be installed in two directions. Thanks to their own tensile strength, they provide a tensile resistance to the soil and increase its mechanical characteristics. High Modulus Tenax LBO HM geogrids and Tenax GT HM geocomposites are designed to provide higher performance at low strains, i.e. under real operating conditions.

Ballast reinforcement

The ballast reinforcement is fundamental to decrease maintenance costs. Tenax LBO 370 geogrids are certified by British and Dutch Rail Authorities and are designed to improve the characteristics of ballast used in railway bases.

Retaining structures

With Tenax RIVEL reinforced soil system and Tenax T-BLOCK block system, small base embankments have been built all over the world, reducing costs and time to implement them. The new Tenax PANEL system provides an alternative to traditional reinforced concrete walls, because it is quick to install and offers a wide range of textures.

Slope protection

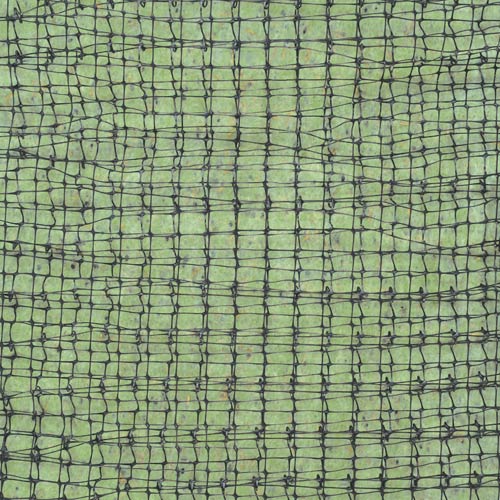

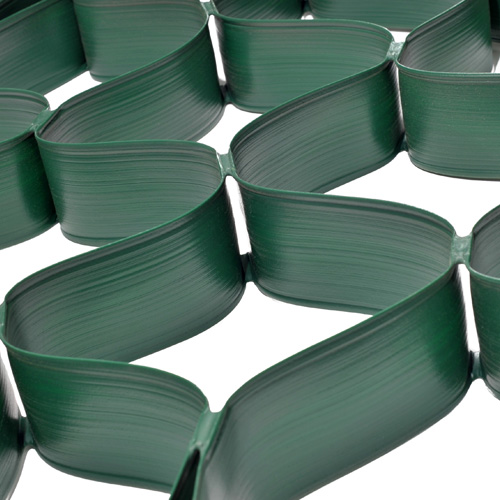

Weather elements can cause slope run-off, thus impeding the growth of vegetation and creating ruts and canals. The Tenax MULTIMAT three-dimensional geomat and the Tenax TENWEB geocells are products designed for slope protection that have been widely tested. They are easy to install, therefore there is no need of special machinery.