Raw materials

Raw materials

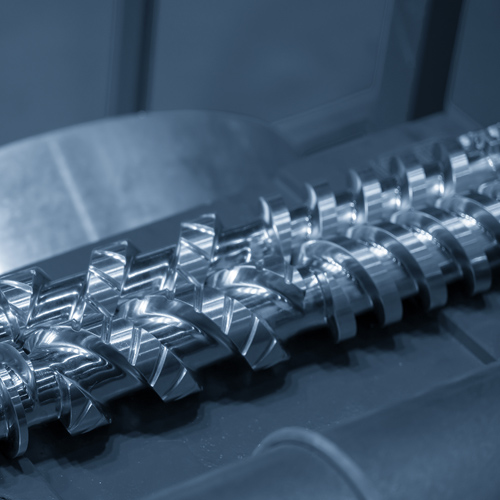

TENAX industrial nettings are manufactured through the extrusion of polyolefins and polyamides, which show an outstanding resistance against any chemicals and micro-organisms such as spores, molds, and bacteria. However, customers must be aware that any raw material has its particular physical features.

hPP – Homopolymer polypropylene

- Specific weight: 0.9-0.915 g/cm3 (56.19-57.12 lb/ft3)

- Melting temperature: 162-168°C (323.6-334.4°F)

- Tensile strength: 34-37 MPa

- Young’s modulus: 1200-2000 Pa

- Yield elongation: 5-10%

- Break elongation: 500-700%

- Working temperature: +0°C – +90°C (32°F – 194°F)

- Max working temperature (short period): +100°C (212°F)

Light material, resistant to chemical substances (as salts, acids and strong alkalis) and with a high mechanical strength. It is used for bi-oriented (stretched) products. Suitable for direct food contact.

cPP – copolymer polypropylene

- Specific weight: 0.895-0.9 g/cm3 (54.62-56.19 lb/ft3)

- Melting temperature: 160-170°C (275-334.4°F)

- Tensile strength: 25-30 MPa

- Young’s modulus: 1000 Pa

- Yield elongation: 5-10%

- Break elongation: >500%

- Working temperature: -20°C – 70°C (68°F – 158°F)

- Max working temperature (short period): +80°C (176°F)

Slightly softer and more resistant to high temperature than the homopolymer but with similar mechanical features. Suitable for direct food contact.

LDPE – Low-density polyethylene

- Specific weight: 0.915-0.920 g/cm3 (57.12-57.43 lb/ft3)

- Melting temperature: 105-118°C (221-244.4°F)

- Tensile strength: 10-25 MPa

- Young’s modulus: 150-300 Pa

- Yield elongation: –

- Break elongation: 550-600%

- Working temperature: -70°C – +40°C (-94°F – 104°F)

- Max working temperature (short period): 50°C (122°F)

Very soft material. It is mostly used for elastic sleeves for protecting goods. Can stand really low temperature.

HDPE – High-density polyethylene

- Specific weight: 0.94-0.96 g/cm3 (58.68-59.93 lb/ft3)

- Melting temperature: 126-135°C (258.8-275°F)

- Tensile strength: 25-35 MPa

- Young’s modulus: 800-1400 Pa

- Yield elongation: 10-12%

- Break elongation: >800%

- Working temperature: -40°C – +70°C (-40°F – 158°F)

- Max working temperature (short period): 75°C (167°F)

Outperforming chemical and good mechanical resistance. Within the polyethylene family it is the one which can stand at best high and low temperatures. It’s used for both extruded and stretched grids.