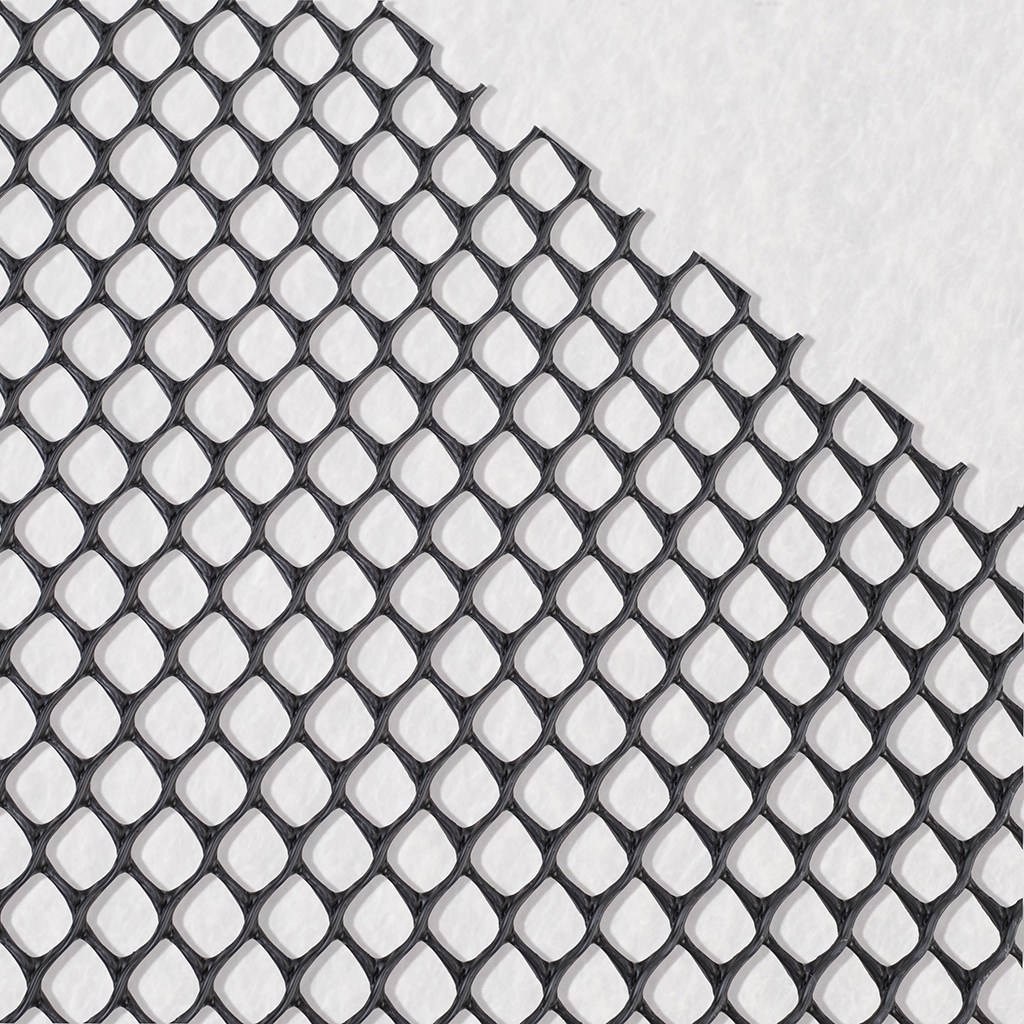

The innovative bi-polymer structure of the drainage net is the result of Tenax's long experience and in-depth knowledge in the transformation of thermoplastic polymers: thanks to technology developed in-house, Tenax is able to offer new products that are increasingly high-performance and reliable.

The HDPE+EVA bi-polymer mesh is manufactured using a single continuous extrusion process, and the two polymers form a single rhombic mesh element that is tested with different inclinations and materials.

The friction resistance at the interface between two geosynthetics can be measured using a specific test, described in European standard EN 12957-2.

The apparatus consists of a rigid board with a hinge at one end; by means of a mechanical transmission system, the board is tilted from its initial horizontal position, increasing the slope at a constant angular velocity of 3° per minute.

A box is placed on top of this surface, connected to it by a low-friction wheel system, which can slide freely on the surface.

The geosynthetics for which the interface friction angle is to be determined are positioned one on the horizontal plane and one inside the movable box. A plate connected to counterweights capable of exerting a nominal load of 5 kPa on the contact surface is placed on the latter.

When the inclination of the equipment reaches the limit angle for the interface, the upper box slides and the test ends. The interface friction angle is determined from the measured angle.