Filtration

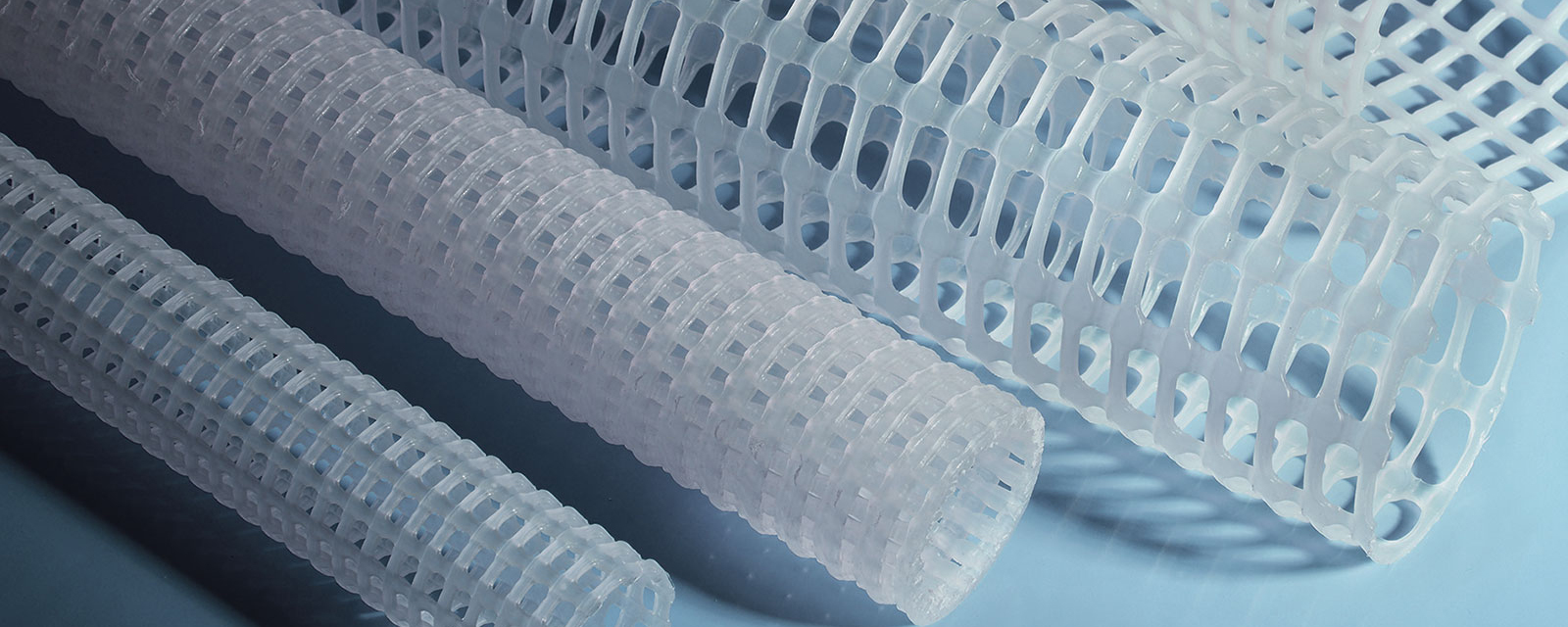

Using advanced technology in the field of thermoplastic extrusion, TENAX designs and manufactures a complete range of high-quality extruded nets, including rigid perforated tubes, diamond-shaped drainage nets, mono- and bi-planar nets, and elastic tubular nets.

Our solutions are developed to meet the needs of manufacturers of filter elements used in:

Water and liquid filter cartridges – Cabin filters for automotive and HVAC – Reverse osmosis (RO) filter modules – Pleated membrane systems

Key benefits

- Lightweight, custom-made structures

- Fully recyclable materials, ideal for more sustainable production

- Excellent chemical stability for long-lasting performance

- Compatibility with ultrasonic and low-temperature welding, for extensive assembly flexibility

Pleat support

Pleating nets are fundamental components in the production of high-performance filter cartridges. They are used to stabilize the filter material during the folding (pleating) process, ensuring uniformity, resistance, and maximum filtering surface area.

External protections for filters

External protective nets for filter cartridges are designed to ensure the durability, safety, and functionality of filtration systems in industrial environments. These nets protect the filter surface from mechanical damage, abrasion, and external contamination.

Perforated rigid tubes

Perforated rigid tubes are structural components used in filtration systems to support filter media, facilitate fluid flow, and ensure mechanical stability. They are commonly used in cartridge filters, depth filters, and custom filtration systems.

Spacers for reverse osmosis filters

Reverse osmosis spacers are key components in membrane modules, designed to optimize water flow, reduce deposit formation, and improve the efficiency of the filtration process. Positioned between the membranes, they promote flow turbulence and help maintain high performance over time.