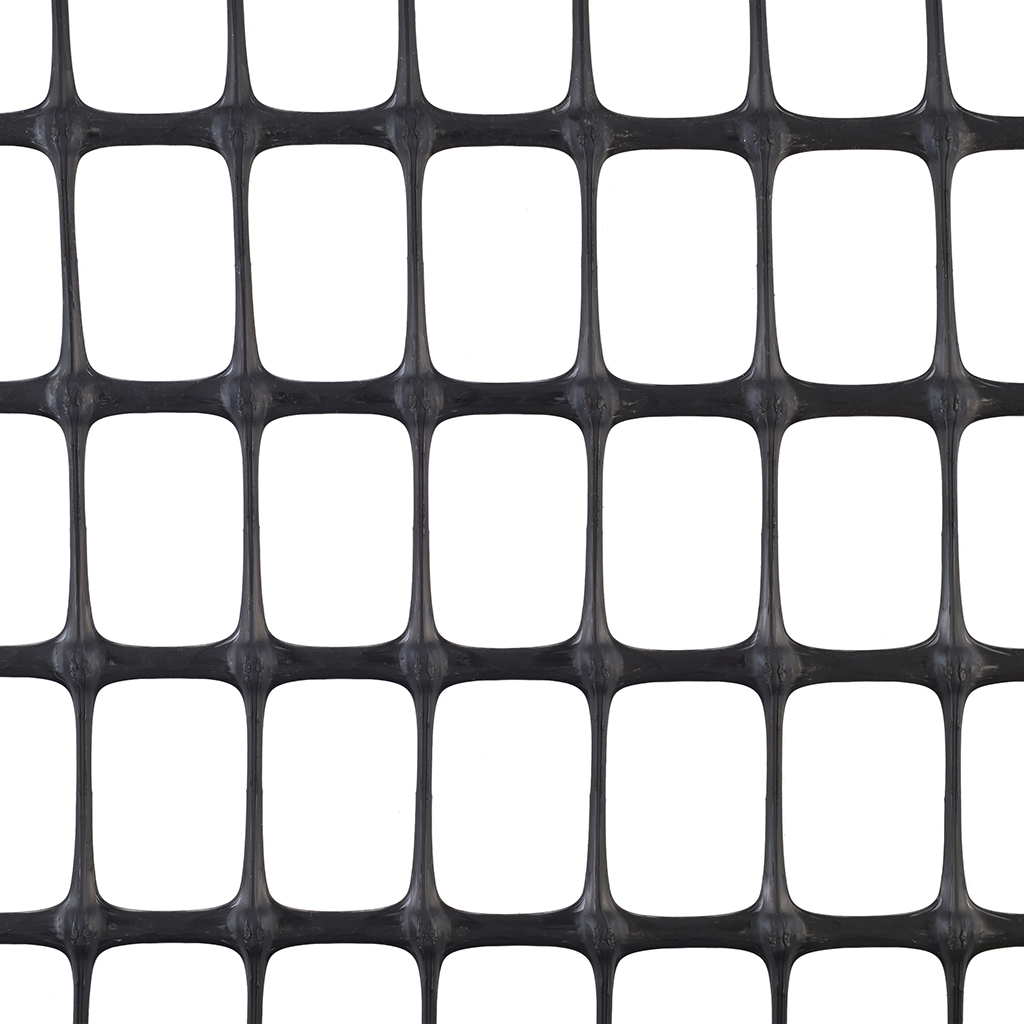

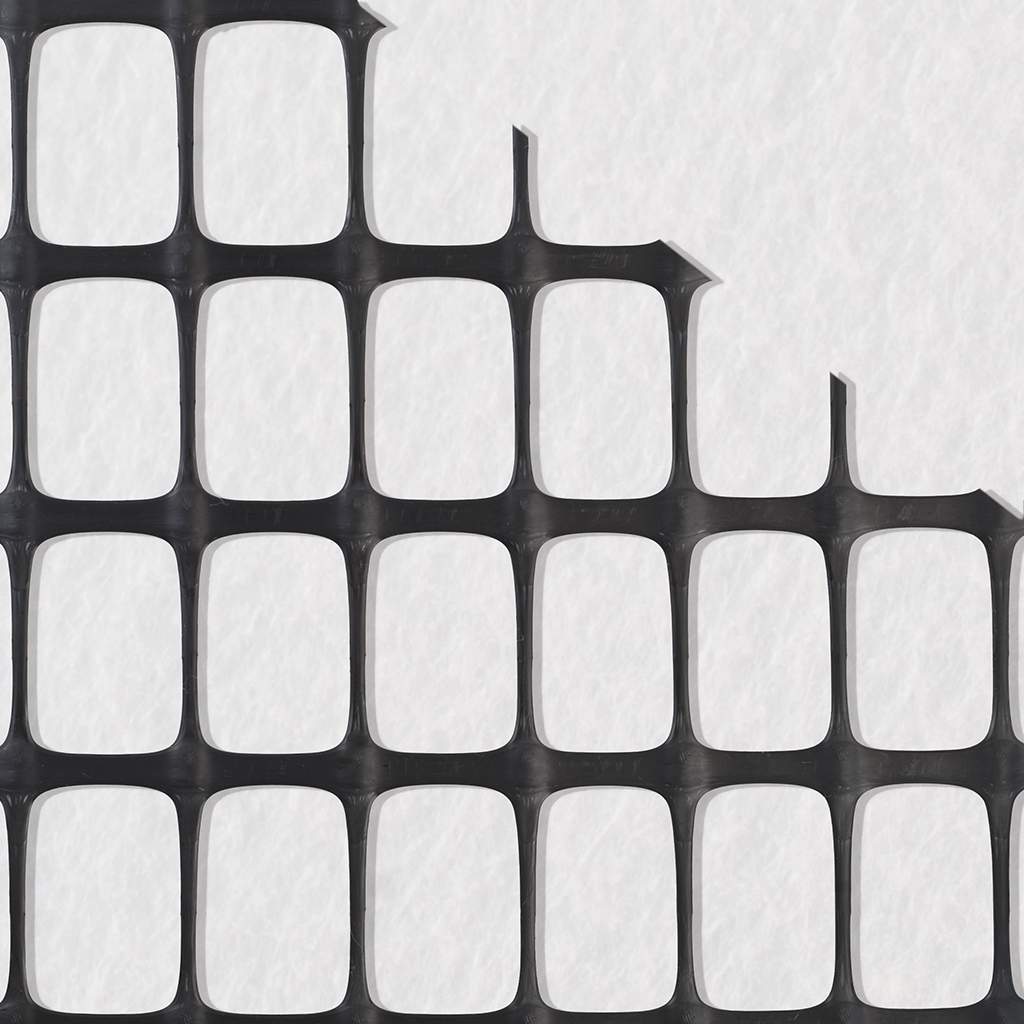

Tenax LBO HM geogrids and Tenax GT HM geocomposites are the evolution of traditional biaxial geogrids with integral joints in extruded polypropylene.

LBO HM geogrids are specifically designed for soil base reinforcement; GT HM geocomposites are produced by industrially laminating an LBO HM geogrid with a geotextile: the geogrid provides resistance to the soil, while the geotextile acts as a separator and filter.

Its uniqueness lies in the increase in elastic moduli, i.e., mechanical performance at low deformations (0.5% and 2.0%).

Considering peak tensile strength as a fundamental parameter for design is not reflected in the actual operating conditions of the structure: in fact, for these values, excessive deformations have now developed that are incompatible with the stability and operation of the structure above.