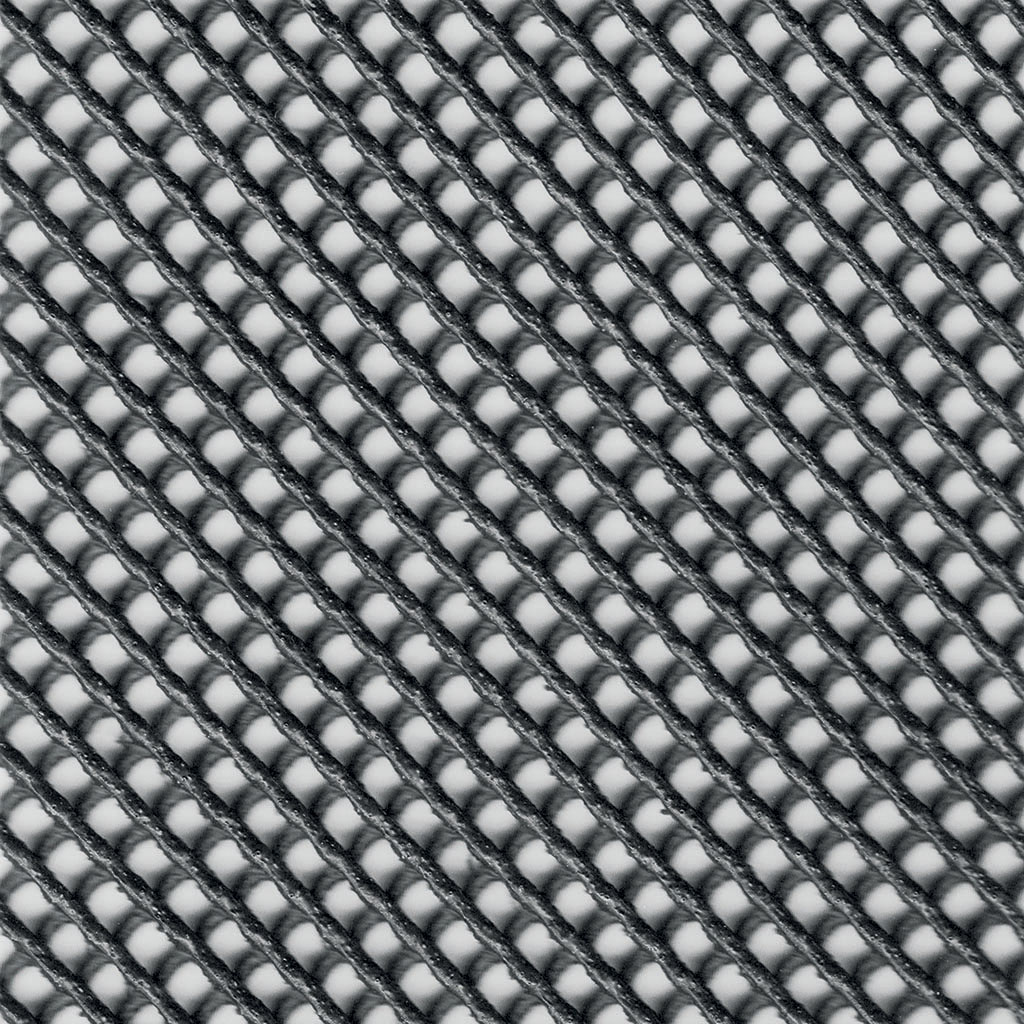

Extruded high-density polyethylene (HDPE) foam mesh with a three-dimensional structure composed of overlapping and intersecting series of parallel wires. Thanks to its structure, it provides effective protection for pipes against possible damage during transport, installation, and backfilling.

CE 4

Extruded rockfall protection net, made of HDPE, 11x10 mm mesh, weight 1200 g/m², thickness 6 mm

Available colors

Features

High protection

Weight

Thickness

Applications

- Mechanical protection of underground pipes and their anti-corrosion coating from possible damage during transport, installation, and backfilling.

Features

- Made of high-density polyethylene (HDPE)

- Three-dimensional structure

- Weight: 1200 g/m²

Benefits

- High resistance to compression, traction, and tearing

- High protective efficacy

- Suitable for pipes of any size

- Total chemical and biological inertia

- Lightweight, flexible, and moldable

| Code | Dimensions (m) | Color | EAN code | CONF/UDV | UDV |

|---|---|---|---|---|---|

| 80004059 | 1 X 20 | BLACK | 8002929014498 | 1 | ROLL |

| 80004289 | 1.5 X 20 | BLACK | 8002929014559 | 1 | ROLL |

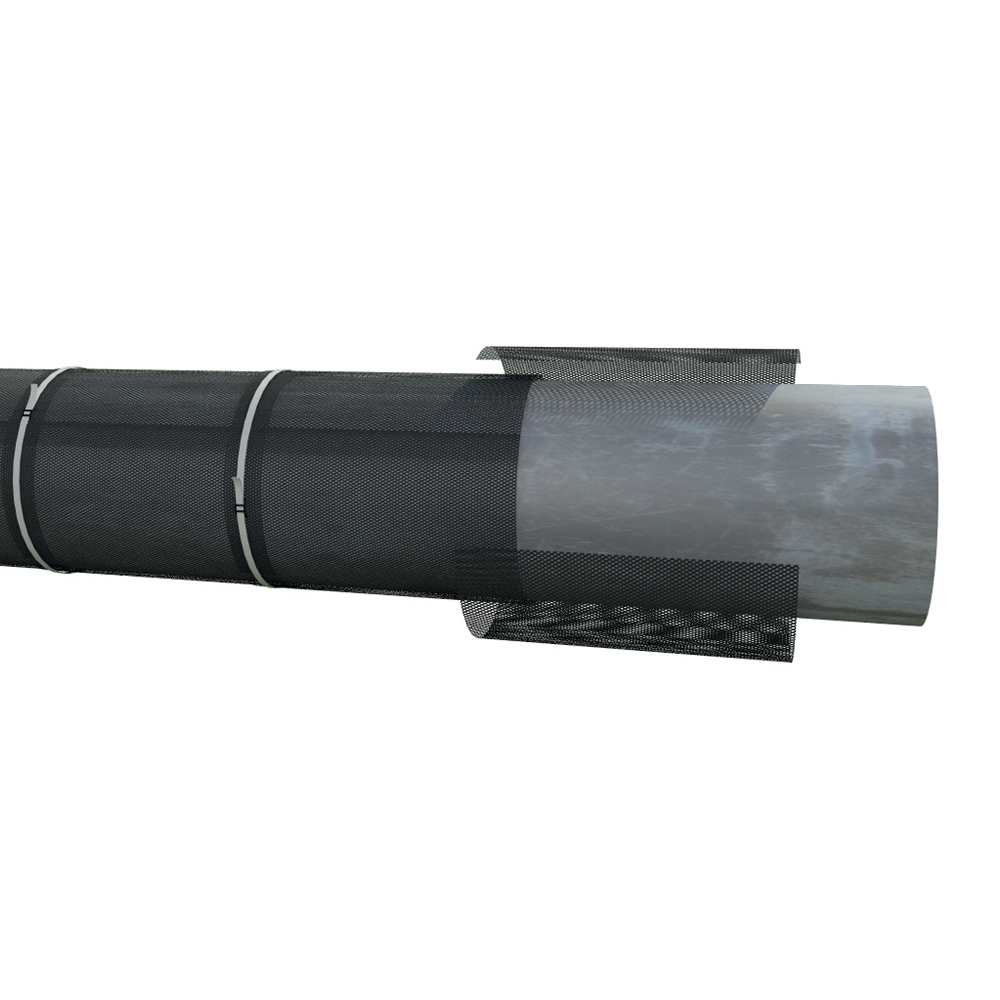

Installation for pipes with reduced circumference

1 – Unroll and unfold the roll parallel to the pipe to be protected.

2 – Position the net under the pipe

3 – Wrap the pipe with the mesh, overlapping the edges by about 15 cm.

4 – Secure the net with plastic or heat-sealed strapping

Installation for pipes with large circumference

1 – Cut the mesh into pieces approximately 15 cm larger than the circumference of the pipe.

2 – Wrap the pipe with the mesh, overlapping it by about 15 cm with the previously applied mesh.

3 – Secure the net with plastic or heat-sealed strapping

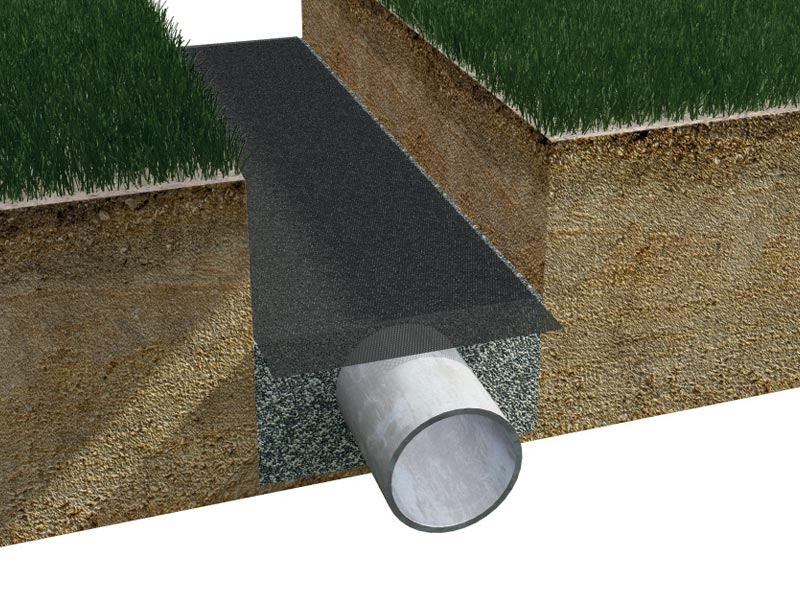

Installation as "capping"

1 – Unroll the roll parallel to the pipe to be protected, which has already been laid in the trench.

2 – Lay the mesh so that it completely covers the top of the pipe.

3 – Proceed with backfilling