Landfills and Contaminated sites

Drainage geosynthetics can provide an alternative to traditional, granular, natural materials required by current legislation for landfill construction and remediation of contaminated sites. Indeed, Tenax geonets and geocomposites enable the drainage of meteoric water, leachate and biogas in cover systems (“capping”), bottom and side slopes.

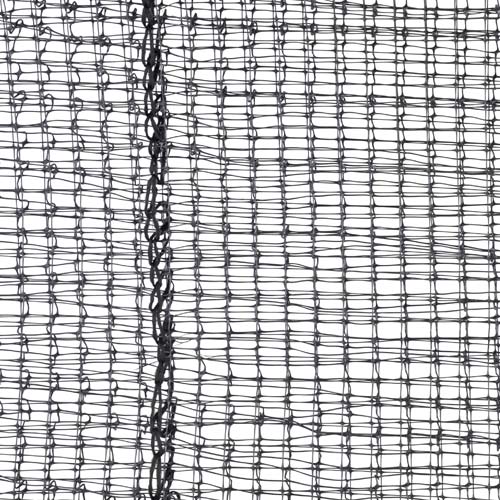

Capping

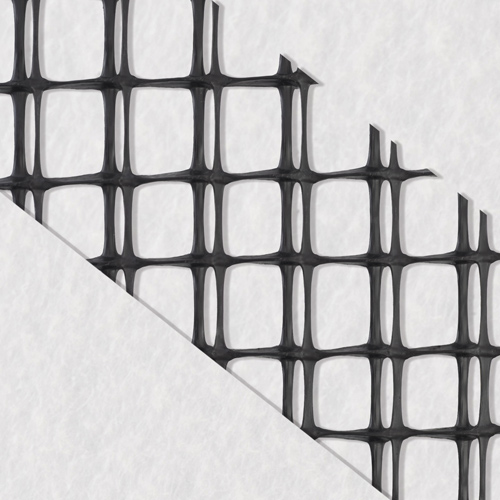

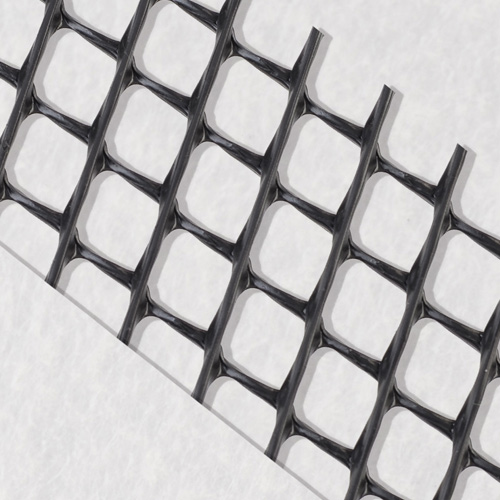

Tenax offers a series of traditional and innovative drainage geocomposites. The high-performing Tenax HD and Tenax HF geocomposites are used when high flow rates are required or when the interface friction angle needs to be higher than traditional products.

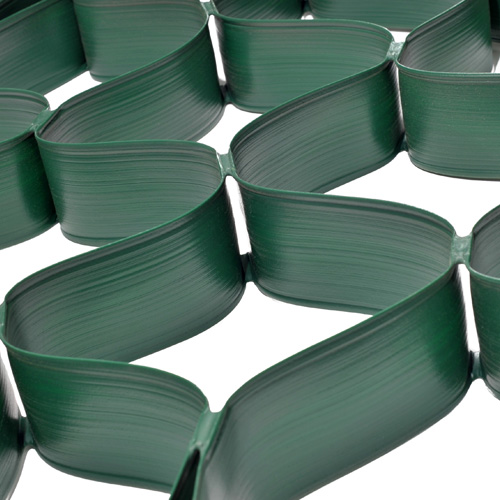

For very long slopes, an element that increases the friction between the cover soil and the waterproofing/drainage system is needed. Tenax MULTIMAT R reinforced geomats enable the soil to “grip” preventing it from slipping because of its weight.

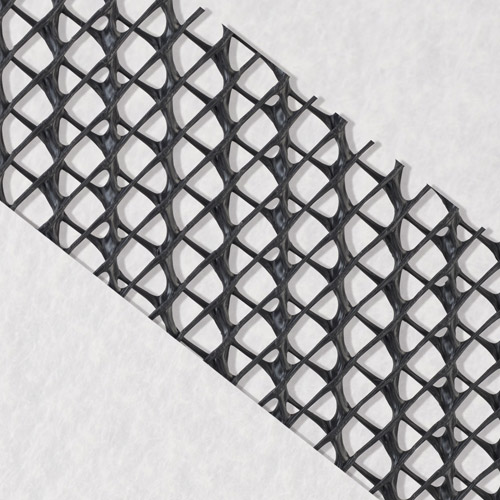

Bottom drainage

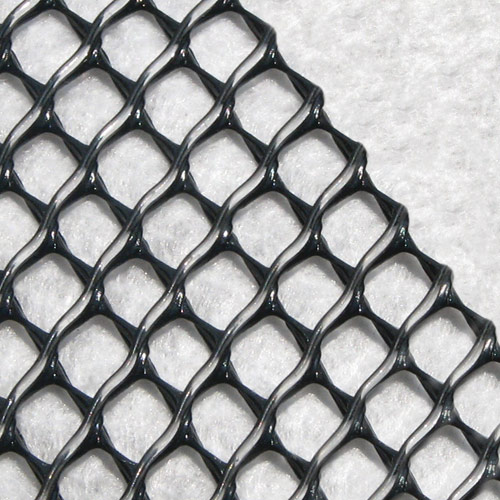

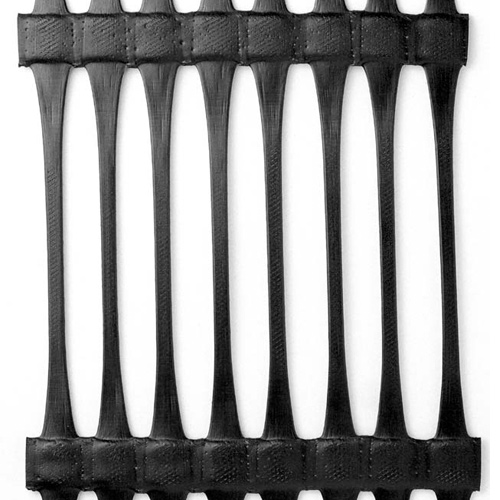

The bottom and the side slopes are subject to the weight of waste, therefore it is fundamental that the drainage materials provide high compressive strength in order to ensure the design flow rate. Tenax TENDRAIN triplanar geocomposites, thanks to their structure with three overlapping and intersecting strands, are specifically designed to drain the leachate even when the waste load is considerable.

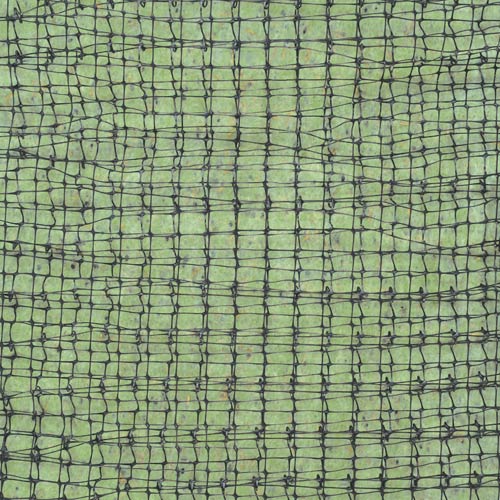

Erosion control

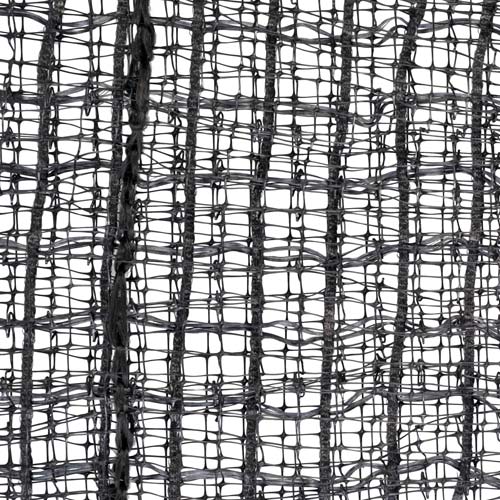

Before a complete revegetation, a landfill covering is subject to run-off and surface erosion phenomena which create ruts and canals that impede the growth of vegetation. Tenax Multimat and Tenax Multimat P geomats perform an important task of erosion control, so vegetation can grow quickly and uniformly.

Containment embankments

To increase a landfill capacity, and thus the return on investment, it is necessary to build superimposed embankments with a limited section. The Tenax RIVEL reinforced soil system ensures embankment stability, enables revegetation and therefore does not impact on the landscape.